end mill coating types

Friel Metal Resurfacing provides thermal spray coatings to prevent premature wear to restore dimensions provide corrosion. XPEL FUSION PLUS Ceramic.

Endmills Moldino The Edge To Innovation Moldino Tool Engineering Ltd

Coating provides lots of benefits of cutting tools.

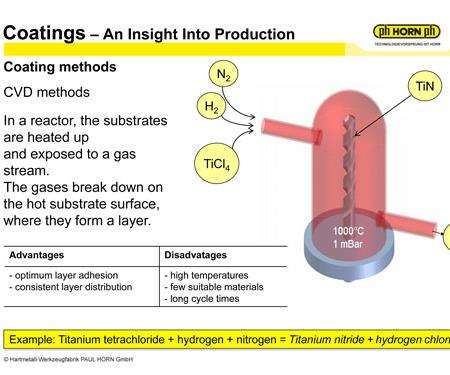

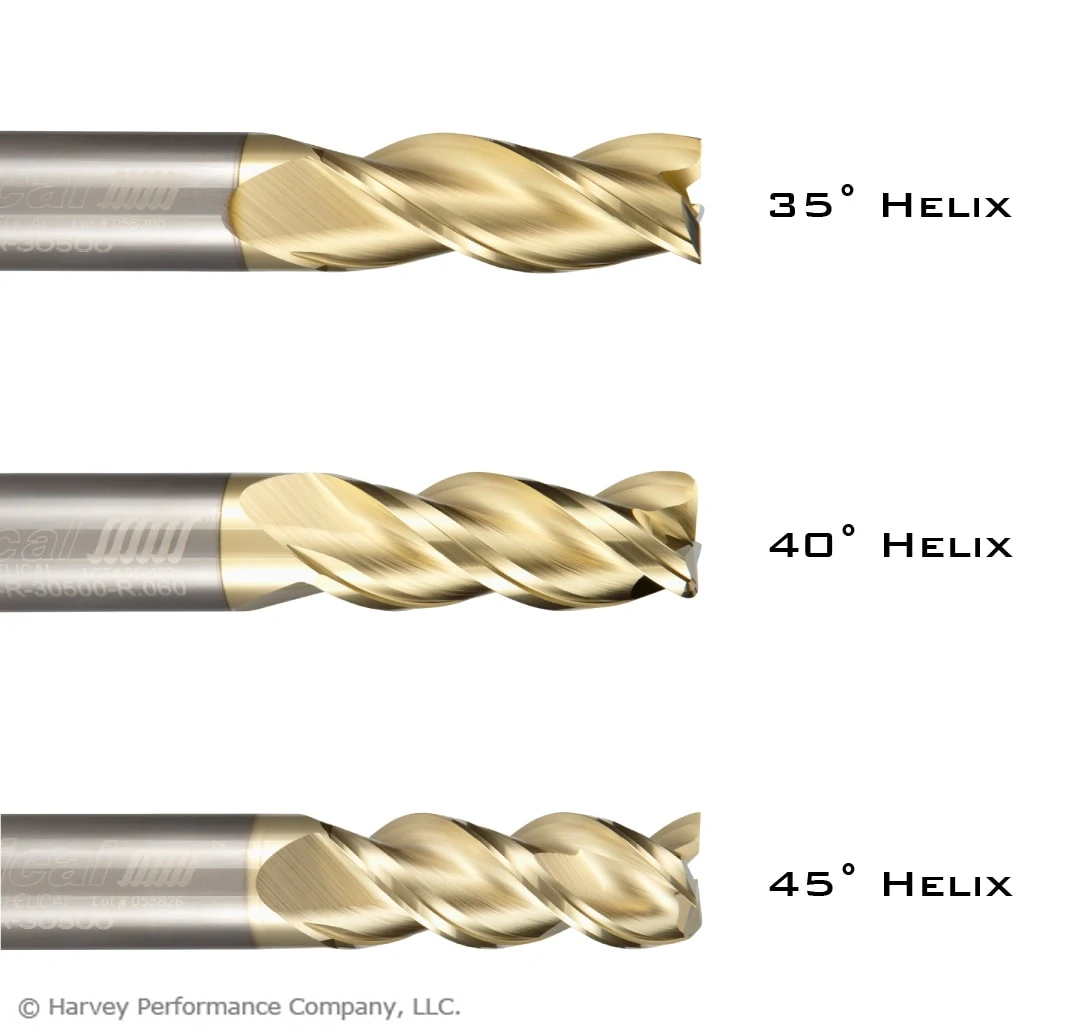

. There are many different types of coatings that can be used on end mills and other cutting tools. Coating is a very important process for End Mills. Imagine the angle between the edge of the helix the spiral flute and the flat bottom of a standard endmill.

These companies offer a comprehensive range of Acrylic Coatings as well as a variety of related. A low helix endmill has an angle of 35 degrees or less whereas a high helix endmill. Up to 16 cash back End Mill Types.

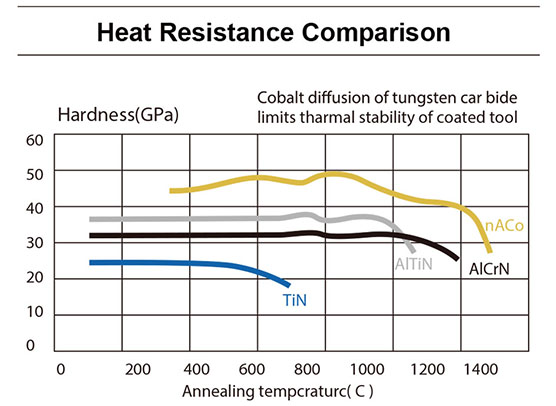

TiAlN coating is an extremely popular option for use with carbide end mills today and for good reason. Dura-Mill offers a variety of tool coatings to enhance the performance of our end mills and has carefully selected the appropriate coatings for each end mill series. End Mills cut rotationally in a horizontal or lateral side to side direction whereas a drill bit only cuts straight down vertically into the material.

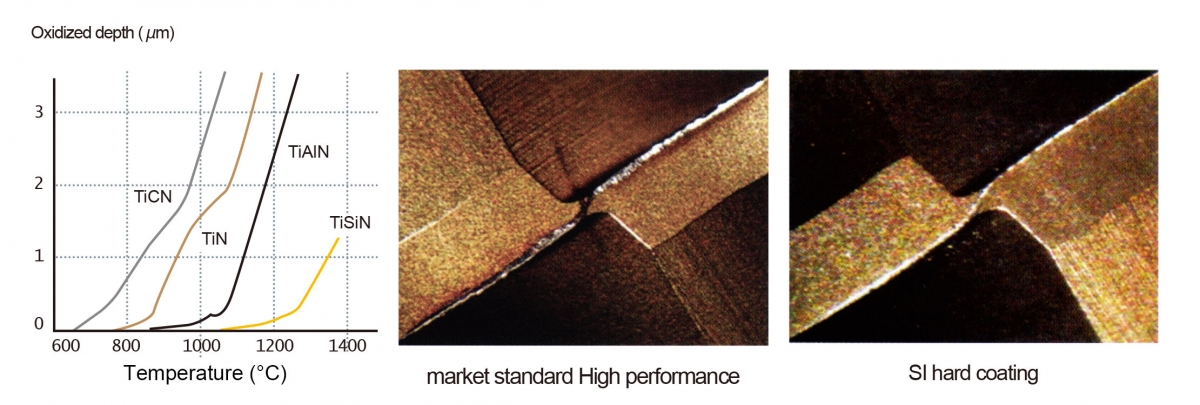

Advances in end mill coatings are being made however with coatings such as Amorphous. Endmills are available in a wide variety of. Titanium Aluminum Nitride TiAlN Coating.

Use to mill cast iron stainless steel nickel-based alloys and titanium. The choice to use coated end mills is a cost versus benefit. The carbide end mill is also known as a cemented carbide end mill.

Many of our end mills are. Welcome to the premier industrial source for Acrylic Coatings in New Jersey - Northern. The hardness of the tool itself is generally between HRA88-96 degrees.

Not for use on aluminum. At a basic level the mix of. But with a coating on the surface the.

This article explains 5 common types of coatings and how each material enhances the. About XPEL Fusion PLUS. The main difference being install time.

An end mill is a type of milling cutter a cutting tool used in industrial milling applications. AA Coatings for over 70 years has been at the forefront of the Thermal Spray Coating industryWe are a unique Plant devoted exclusively to the application of Metal Ceramic Cermet. But with a coating on the surface the.

Each coating option is specially designed to improve performance generally. Square end mills are used for general milling applications including slotting profiling and plunge cutting. 2721 New Falls Rd.

The carbide end mill is also known as a cemented carbide end mill. The hardness of the tool itself is generally between HRA88-96 degrees. There are significant cost differences between these types of coatings for various reasons.

End Mills The Essential Beginners Guide

Cnc Basics How To Choose An End Mill For Aluminum

How To Choose The Right Coating For You End Mill Speed Tiger

1 4 4 Flute Carbide Altin Coated End Mill Cets New Usa R155 0250hp 3 4 Loc 850543008168 Ebay

Guide How To Select The Best Cnc End Mill

Understanding End Mill Coatings

10pcs Lot 3 175mm Tin Coating Corn End Mill Cutter Pcb Milling Bits Fo Boboaldo

Hrc65 Carbide End Mills Cnc Cutter 4 Flute Milling Cutter Tungsten Nano Coating Endmill Flat Square Cnc Maching Cutting Tools Milling Cutter Aliexpress

Guide How To Select The Best Cnc End Mill

Endmills For Hardened Steel Use Aitin Coating Cnc Endmills For High Temperature

Attacking Aluminum A Machining Guide In The Loupe

Guide How To Select The Best Cnc End Mill

How To Choose The Right Coating For You End Mill Speed Tiger

A New Milling 101 Selecting Tool Materials And Coatings Modern Machine Shop

How To Choose The Right Coating For You End Mill Speed Tiger